What is a Garment Trims Factory and What Do They Make

Table of Contents

A garment trims factory produces essential components that complete and enhance garments, such as buttons, zips, ribbons, and labels. You depend on these trims for structural support, usability, and decorative appeal. Trims improve the overall quality of finished products and help you balance design with practical wearability. Functional items like zippers and buttons ensure secure closures and durability, while elastic tapes add comfort and flexibility. As a leading provider, VEKEN supplies a comprehensive range of garment accessories and trims to meet your business needs.

Key Takeaways

- Garment trims factories produce essential components like buttons, zips, and labels that enhance both the function and style of garments.

- Quality control is crucial; rigorous inspections ensure that all trims meet high standards before they reach manufacturers.

- Customisation allows brands to tailor trims to their specific needs, reinforcing brand identity and supporting sustainability goals.

- Choosing eco-friendly materials for trims can help brands appeal to conscious consumers and reduce environmental impact.

- Partnering with a reliable supplier like VEKEN ensures access to high-quality trims and efficient logistics, positioning your business for success.

Garment Trims Factory Explained

What is a Garment Trims Factory

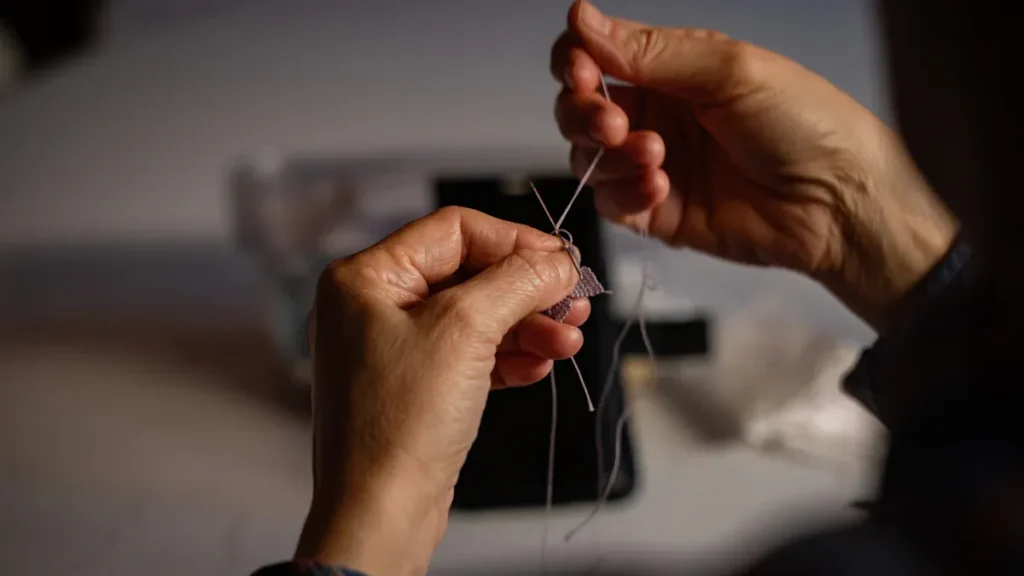

You rely on a garment trims factory to produce the essential finishing elements that elevate your garments. These factories specialise in manufacturing a wide range of trims, such as buttons, zips, ribbons, and labels, which add both function and style. The production process in a garment trims factory follows a structured approach to ensure precision and consistency.

- Cut: Technicians cut fabrics and materials to exact specifications, matching the requirements of each garment.

- Make: Skilled workers stitch the cut pieces together, using advanced sewing machines for accuracy.

- Trim: The final stage involves attaching trims like zippers and buttons, followed by a thorough quality check.

During the trimming process, you benefit from rigorous inspections that remove excess fabric and loose threads, ensuring every item meets strict quality standards before shipment.

Modern garment trims factories use advanced machinery and technology to improve efficiency and accuracy. Recent digital advancements have transformed the garment industry, replacing many traditional practices with automated systems. For example, mechanical stretch technology now allows rigid tapes and labels to become stretchable without chemicals. By applying heat and pressure, manufacturers can create trims suitable for sportswear, offering both versatility and cost savings.

You may notice that the global garment industry is shifting towards more targeted sourcing strategies. Major trade shows, such as the Garment Technology Expo and the Lace & Trims Show, highlight the growing importance of trims like laces, ribbons, buttons, and zippers. These events showcase the latest trends and innovations, helping you stay ahead in a competitive market.

Quality and compliance remain top priorities in any garment trims factory. Factories implement strict monitoring programmes and regular social audits to ensure adherence to international safety and environmental standards. The table below outlines key compliance measures:

| Compliance Measure | Description |

|---|---|

| Monitoring Programme | Regular visits by staff to assess compliance with codes of conduct and local laws. |

| Social Audits | All finished-goods factories undergo social and environmental audits, often by third parties. |

| Chemical and Environmental Impacts | Environmental audits ensure compliance with legislation on chemicals and waste. |

| Remediation of Audit Findings | Factories address substandard findings promptly, focusing on long-term solutions. |

| Training and Education | Ongoing training programmes improve compliance and sustainability practices. |

Despite these efforts, you may encounter challenges in maintaining quality and efficiency. Common issues include fabric defects, sizing errors, stitching problems, colour variations, faulty accessories, and poor finishing. Addressing these challenges requires robust quality control systems and continuous improvement.

VEKEN’s Role in the Industry

You can count on VEKEN as a trusted partner in the garment trims factory sector. VEKEN stands out by combining decades of experience with a commitment to innovation and customer satisfaction. The company offers a comprehensive range of trims and accessories, supporting manufacturers and brands worldwide.

VEKEN invests in advanced technology and quality assurance processes. The company’s factories use modern machinery to produce trims with consistent quality and precision. By adopting digital solutions and mechanical stretch technology, VEKEN delivers products that meet the evolving needs of the garment industry.

You benefit from VEKEN’s focus on compliance and sustainability. The company follows international standards for safety and environmental responsibility, ensuring that every product aligns with your brand values. VEKEN’s team conducts regular audits and provides ongoing training to maintain high standards across all operations.

When you choose VEKEN, you gain access to a diverse product portfolio, reliable logistics, and responsive after-sales support. The company’s expertise helps you overcome common industry challenges, from sourcing high-quality trims to ensuring timely delivery. VEKEN’s role in the garment trims factory landscape positions your business for success in a dynamic and demanding market.

Types of Trims and Accessories

You encounter many types of trims and accessories in garment production. These elements play a vital role in both the appearance and performance of your garments. VEKEN offers a wide selection of trims, allowing you to choose the best options for your needs.

Visible Trims (Buttons, Zips, Ribbons)

Visible trims stand out on finished garments. You use these trims to add function and style.

- Buttons: You can select from resin, metal, wood, shell, coconut, or pearl buttons. These fasten garments securely and add decorative flair.

- Zips: Nylon, resin, and metal zips provide reliable closures. You often use them in jackets, trousers, and dresses.

- Ribbons: Satin, grosgrain, and jacquard ribbons enhance the look of garments. You apply them for decorative borders or as functional drawstrings.

- Threads: You rely on threads for stitching, embroidery, and visible detailing. Threads come in cotton, polyester, and blends, supporting both durability and design.

- Pins: You use pins for temporary holds during assembly or as decorative accents.

- Handmade Sets: These sets include threads, needles, and small accessories for bespoke or limited-edition pieces.

- Cords & Tapes: You use cords and tapes as drawstrings or decorative elements, often made from eco-friendly materials.

Tip: Choosing eco-friendly materials for visible trims helps you meet sustainability goals and appeal to conscious consumers.

Invisible Trims (Interlinings, Tapes)

Invisible trims work behind the scenes. You do not see them, but they are essential for garment structure and longevity.

- Interlinings: You insert interlinings between fabric layers to provide shape and support.

- Tapes: You use tapes to reinforce seams and edges, preventing fraying and wear.

- Threads: You select threads for internal stitching, ensuring strength without bulk.

- Fabric: You choose special fabrics for linings and support, often prioritising eco-friendly materials.

You benefit from invisible trims in several ways:

- They provide structural support to garments.

- They enhance the fit, ensuring garments conform well to the body.

- They reinforce specific areas to prevent wear and tear.

- They help maintain shape and prevent stretching over time.

| Material Type | Description |

|---|---|

| Interlining | Used inside garments, not visible from outside. |

| Lining | Also used internally, serves a similar purpose. |

You often choose eco-friendly materials for invisible trims to improve garment sustainability.

Branding Trims (Labels, Tags, Patches)

Branding trims help you communicate your brand identity. You use these trims to make your garments stand out in the market.

- Labels: Woven, printed, metal, leather, PVC, rubber, silicone, and TPU labels display your brand name and care instructions.

- Tags: Hang tags and swing tags provide product information and branding.

- Patches: Embroidered or woven patches add unique branding or decorative elements.

- Threads: You use threads to attach branding trims securely and neatly.

Branding trims act as visual identifiers. They convey your brand’s values and enhance recognition. Custom workwear demonstrates how branding trims transform employees into brand ambassadors, making your brand more visible.

| Printing Technique | Suitable Materials | Key Features |

|---|---|---|

| Screen Printing | Textile items (t-shirts, tote bags) | Ideal for large designs with vibrant colours |

| Digital Transfer Printing | Vinyl, various fabrics | Best for multi-colour prints, suitable for small runs |

| Direct-to-Garment (DTG) | Cotton, polyester, blends | Direct ink application for detailed designs |

| Direct-to-Film (DTF) | Cotton, polyester, blends | High-resolution prints with longevity |

| Transfer Print | Vinyl, various fabrics | Uses heat application for finishing |

You can request custom branding trims in bulk trims for ready-to-wear collections. VEKEN supports you with a wide range of eco-friendly materials and threads for every branding need.

You see that different types of trims serve unique purposes. You select from visible, invisible, and branding trims to achieve the right balance of function, style, and brand impact. VEKEN’s range covers all types of trims and accessories, ensuring you find the right solution for every garment.

Customisation in Garment Trims

Custom Options at VEKEN

You understand that customisation is essential when selecting the right trims for your garments. VEKEN provides a wide range of customised solutions, allowing you to tailor trims to your brand’s specifications. You can choose from various materials, colours, shapes, and finishes. This flexibility helps you meet the demands of manufacturers and fashion brands that require unique features for their collections.

Customisation supports sustainable garment making by enabling you to select eco-friendly materials and production methods. You can request trims made from recycled polyester, organic cotton, or biodegradable plastics. VEKEN’s team works with you to develop trims that align with your sustainability goals and quality standards.

You benefit from VEKEN’s advanced technology and design expertise. The company offers digital mock-ups, sample production, and bulk manufacturing. You receive consistent quality and reliable delivery, whether you need woven labels, embroidered patches, or custom buttons.

| Customisation Feature | Options Available | Benefit to You |

|---|---|---|

| Material Selection | Polyester, cotton, metal, wood | Matches brand values |

| Colour Matching | Pantone, custom shades | Ensures brand consistency |

| Shape & Size | Standard or bespoke dimensions | Fits specific garment designs |

| Finish | Matte, glossy, textured | Enhances visual appeal |

Benefits of Customisation

You gain several advantages by investing in customisation for garment trims. Custom trims help you reinforce your brand identity and differentiate your products in the market. You can add logos, slogans, or unique design elements to labels and tags, making your garments instantly recognisable.

Customisation also supports sustainable garment making. You can select trims that reduce environmental impact and improve product longevity. This approach appeals to conscious consumers and strengthens your reputation as a responsible manufacturer.

You improve efficiency by streamlining the sourcing process. VEKEN’s customised solutions allow you to order trims that fit your production schedule and technical requirements. You avoid delays and ensure that every detail meets your expectations.

Tip: Custom trims provide a competitive edge by combining quality, sustainability, and brand impact. You position your business as a leader in innovation and responsible manufacturing.

You see that customisation in garment trims is not just about aesthetics. It is a strategic choice that supports your business goals, enhances product quality, and promotes sustainable garment making.

Functions and Value of Trims

Functional Roles

You rely on essential trims to improve the performance and durability of your products. High-quality trims such as zippers, buttons, and tapes serve as decorative and functional additions. These components help you secure closures, reinforce seams, and maintain the structure of garments. You use interlinings and tapes to provide shape and support, which ensures that each piece retains its form after repeated wear and washing.

In the garment industry, you often face demands for both style and practicality. Essential trims address these needs by offering solutions that withstand daily use. For example, you select robust zippers for outerwear to guarantee reliable fastening. You choose strong buttons for shirts and trousers to prevent accidental openings. These roles in garment making are vital for manufacturers who want to deliver products that meet high standards of quality and longevity.

Note: High-quality trims reduce the risk of product returns due to malfunctioning closures or weak seams, supporting your reputation for excellence.

Aesthetic and Branding Impact

You understand that trims do more than serve practical purposes. They also play a critical role in shaping the visual identity of your garments. Trims such as embroidered patches, woven labels, and custom tags allow you to showcase your brand and differentiate your products in a crowded market. These roles in garment making extend beyond function, influencing how consumers perceive your collections.

Trims enhance the aesthetic appeal and perceived value of garments in consumer markets. You use decorative elements to elevate the look and feel of each piece, making your products more attractive to buyers. Branding trims, including labels and patches, communicate your brand’s story and values. This connection helps you build loyalty and recognition in the garment industry.

| Trim Type | Functional Role | Branding/Aesthetic Value |

|---|---|---|

| Buttons | Fastening, structure | Style, customisation |

| Zippers | Secure closure | Modern look, colour options |

| Labels & Tags | Information, care | Brand identity, differentiation |

| Patches | Reinforcement | Decoration, storytelling |

You gain a competitive edge by selecting essential trims that combine durability, style, and branding. VEKEN supports you with a wide range of high-quality trims designed to meet the evolving needs of the garment industry.

You rely on a garment trims factory to supply essential components for garments. These factories produce a wide range of trims that support both function and brand identity in the garment industry. Trims improve quality and help manufacturers meet market demands. In the garment industry, you need reliable partners. VEKEN delivers expertise, advanced solutions, and consistent value for your business.

Choose VEKEN to enhance your products and strengthen your position in the market.

FAQ

What types of trims can you source for different garments?

You can source trims such as buttons, zips, ribbons, labels, and patches for various garments. VEKEN offers options in multiple materials and styles, helping you match trims to your product requirements.

How does VEKEN ensure consistent quality in garment trims?

You benefit from VEKEN’s multi-tiered quality control system. The team inspects every batch, uses advanced machinery, and follows strict standards. This process guarantees reliable trims for your production needs.

Can you request custom trims for specific manufacturers or brands?

You can request custom trims tailored to your specifications. VEKEN supports manufacturers with bespoke solutions, including unique colours, shapes, and branding elements to meet your design and production goals.

What is the typical lead time for bulk orders of garment trims?

You usually receive bulk orders within two to four weeks, depending on the complexity and quantity. VEKEN’s logistics team coordinates with you to ensure timely delivery and efficient supply chain management.

Are eco-friendly trims available for sustainable garment production?

You can choose eco-friendly trims made from recycled or biodegradable materials. VEKEN offers sustainable options to help you meet environmental standards and appeal to conscious buyers.

Quick Link

Contact

Phone

0086-574-87208762

info@vekenindustry.com

Address

Floor 18, Yuehu Jinhui Tower, 225 Liuting Street Haishu District,Ningbo,China 315010

Copyright CleanMonk © 2025 All Rights Reserved