Hook And Loop Tape Factory Comparison Guide For Buyers

Table of Contents

Buyers often ask how to choose the best hook & loop tape factory for their needs. Selecting the right factory impacts product quality, pricing, and reliability. VEKEN stands out as a trusted manufacturer in garment accessories and trims. Many buyers face challenges such as material quality, backing type, strength rating, environmental resistance, and performance consistency. Careful evaluation helps buyers find solutions that fit their requirements.

Key Takeaways

- Evaluate material selection, environmental resistance, and product specifications to ensure compatibility with your needs.

- Choose factories with adequate capacity and modern equipment to guarantee timely delivery and stable production.

- Look for certifications like ISO 9001 and Oeko-Tex to ensure product quality and compliance with industry standards.

- Request samples and conduct pilot orders to test product performance before committing to large purchases.

- Consider customization options to meet specific project requirements and enhance the functionality of your products.

Choosing A Hook & Loop Tape Factory

Key Buyer Questions

Buyers often face several important questions when selecting a hook & loop tape factory. They want to know how to ensure consistent quality, what level of customization is available, and how reliable the delivery process will be. Many also ask about the factory’s ability to handle large orders and meet specific industry standards. To make an informed decision, buyers should focus on three main criteria:

- Material selection that matches the application’s needs.

- Environmental resistance to ensure performance in various conditions.

- Product specifications that guarantee compatibility and durability.

These questions help buyers compare vendors and identify which factory can best support their business goals.

Why Factory Selection Matters

Choosing the right hook & loop tape factory shapes the long-term success of any supply chain. The factory’s location, capacity, and compliance standards all influence cost, reliability, and delivery speed. The table below highlights key factors that impact supply chain performance:

| Evidence Point | Description |

|---|---|

| Sourcing Geographies | Tariff-driven input cost volatility has led manufacturers to reconsider sourcing locations to maintain margins and reliability. |

| Supplier Relationships | Firms with diversified supplier networks show greater agility in managing costs and commitments. |

| Compliance Importance | Compliance and customs advisory functions are crucial in supplier selection to meet regulatory requirements. |

| Logistics Impact | Proximity to end markets can reduce lead times, while regional regulations affect supplier network design. |

| Supplier Capacity | Selecting suppliers with adequate capacity ensures stable production and timely delivery during peak demand. |

When comparing vendors, buyers should look for factories with more than 2,000 m² of floor space, a workforce of at least 50 employees, and modernized equipment. These features support stable production and timely delivery.

VEKEN stands out as a leading manufacturer with decades of experience and a strong reputation for quality. The company’s advanced facilities and global reach make it a preferred partner for brands seeking reliable garment accessories and trims. Careful factory selection ensures buyers receive products that meet their standards and support their business growth.

Understanding Hook And Loop Tape

What Is Hook And Loop Tape

Hook and loop tape is a fastening system that uses two components: one side features tiny hooks, and the other side has small loops. When pressed together, the hooks catch the loops, creating a secure closure that users can open and close repeatedly. This technology offers a simple, reusable solution for many fastening needs. Manufacturers use materials like nylon, polyester, and plastic resins to produce industrial hook and loop tape. Each material provides unique performance characteristics. Nylon delivers high cycle life and heat resistance. Polyester offers moisture and UV resistance, making it suitable for outdoor applications. Plastic resins allow for custom stiffness or flexibility in molded hooks.s

The global market for hook and loop tape in garment accessories continues to grow. In 2024, the market size reached an estimated USD 2.37 billion. The projected annual volume stands at 2.5 billion units, with the footwear and apparel segment accounting for 55% of total usage. Over 1.3 billion units serve apparel applications each year. This growth highlights the importance of reliable suppliers like VEKEN, who offer a wide range of garment trims and accessories, including custom hook and loop tape for clothing manufacturers and designers.

Industrial Applications

Industrial hook and loop tape plays a vital role in many sectors. Its versatility supports a wide range of applications, from garment manufacturing to advanced engineering. The following table outlines common industries and their leading application examples:

| Industry | Application Example |

|---|---|

| Cable Management | Bundling and securing cables in data centers and electronics |

| Personal Protective Equipment | Adjustable straps and closures on PPE like masks and gloves |

| Modular Fixtures | Reconfigurable assembly lines and retail displays |

| Wearable and Consumer Products | Adjustable straps on fitness trackers and clothing |

| Automotive and Aerospace | Securing panels and wiring harnesses in vehicles |

Manufacturers rely on industrial hook and loop tape for adjustable closures, quick-release systems, and modular designs. In garment accessories and trims, designers use it for children’s wear, sports gear, and uniforms. VEKEN’s product range supports these applications with custom solutions, ensuring durability and performance for every use case.

Factory Comparison Criteria

Selecting the right hook & loop tape factory requires a clear understanding of several comparison criteria. Buyers should evaluate vendors based on product range, customization, quality, certifications, pricing, delivery, and support. These factors help ensure reliable adhesive hook and loop solutions for a wide range of applications.

Product Range & Customization

A strong product range allows vendors to serve diverse applications, from garment manufacturing to industrial assembly. Leading factories offer a variety of adhesive hook and loop tapes, including high-performance tapes for demanding environments. Customization options play a key role in meeting unique project requirements. The table below outlines common customization aspects available from top factories:

| Customization Aspect | Description |

|---|---|

| Size Adjustments | Modify tape dimensions for specific applications. |

| Color Matching | Match colors to client specifications. |

| Backing Type Modifications | Select from multiple backing materials. |

| Logo Branding | Add custom branding to adhesive hook and loop. |

| Tailored Packaging | Choose packaging that fits distribution needs. |

Factories like VEKEN provide customized fastening solutions, including different cutting technologies, adhesive backing types, and pre-cut options. This flexibility supports applications in apparel, automotive, and electronics.

Quality & Certifications

Quality remains a top priority for any hook and loop tape project. Buyers should look for factories with robust quality management systems. Key certifications include ISO 9001 for quality management, Oeko-Tex Standard 100 for chemical safety, and REACH or RoHS for compliance in regulated markets. These certifications ensure adhesive hook and loop products meet international standards and perform reliably in all applications. VEKEN maintains strict quality controls and holds relevant certifications, supporting consistent results for every order.

Pricing & Value

Pricing varies among hook & loop tape factory options. Factors such as automation, order volume, and customization influence cost. Zhejiang suppliers often offer lower pricing due to economies of scale, while Guangdong vendors provide faster sampling and more flexible customization. The table below compares typical pricing models:

| Factor | Zhejiang Suppliers | Guangdong Suppliers |

|---|---|---|

| Pricing | Lower, scale-driven | Slightly higher, better service |

| Customization Flexibility | Limited | High |

| Minimum Order Quantities | 10,000+ meters | 1,000 meters (trial runs) |

VEKEN delivers competitive pricing and value by combining efficient production with a wide range of adhesive hook and loop solutions for different applications.

Delivery & Support

Reliable delivery and responsive support are essential for buyers in the adhesive hook and loop market. Leading vendors offer fast shipping, clear communication, and after-sales assistance. VEKEN stands out with its global logistics network and VIP shipping status, ensuring timely delivery for high-volume and custom orders. Buyers benefit from dedicated support teams who help resolve issues and optimize applications for the hook-and-loop system.

Tip: Always request samples and review support policies before finalizing a partnership with any hook & loop tape factory.

Top Hook & Loop Tape Factories

Leading Brands Overview

The hook and loop tape industry features several prominent companies that set the standard for quality and innovation. These manufacturers have established strong reputations in the market by delivering reliable fastening solutions for a wide range of applications. The following list highlights the top five global hook and loop tape companies recognized for their market share and product excellence:

- Velcro: The original manufacturer, Velcro, leads the industry with a broad product range and continuous innovation.

- 3M: Known for advanced adhesive technologies, 3M offers hook and loop tape for both industrial and consumer markets.

- APLIX: This French company specializes in fastening solutions and is recognized for high-quality products.

- Kuraray Group: Based in Japan, Kuraray focuses on developing innovative materials and fastening technologies.

- YKK: Renowned for zippers, YKK also produces durable and reliable hook and loop fasteners.

These companies have built global supply networks and serve industries such as apparel, automotive, electronics, and medical devices. Their commitment to research and development drives new product features and improved performance.

Note: Buyers should consider the strengths of each manufacturer when selecting a hook & loop tape factory for their specific needs.

VEKEN’s Position In The Market

VEKEN stands out among hook and loop tape manufacturers due to its comprehensive product offerings and global reach. Originating in Ningbo, China, VEKEN has evolved into a trusted supplier for garment accessories and trims. The company exports to over 120 countries and serves more than 500 clients worldwide. VEKEN’s advanced manufacturing capabilities support high-volume orders and custom solutions for clothing brands, factories, and designers.

VEKEN’s commitment to quality, innovation, and customer satisfaction positions it as a preferred partner in the market. The company provides a wide range of garment trims, including custom hook and loop tape, and maintains strict quality control standards. VEKEN’s logistics network ensures timely delivery, while its after-sales support helps clients optimize their supply chain operations.

Tip: VEKEN’s expertise in customization and reliable delivery makes it an excellent choice for buyers seeking tailored garment accessories and trims.

Comparison Table

The following table compares notable companies in the hook and loop tape market based on key criteria important to buyers:

| Company | Headquarters | Product Range | Customization | Certifications | Delivery & Support | Market Focus |

|---|---|---|---|---|---|---|

| Velcro | USA | Extensive | High | ISO, Oeko-Tex | Global | Industrial, Consumer |

| 3M | USA | Wide | Moderate | ISO, REACH, RoHS | Global | Industrial, Medical |

| APLIX | France | Specialized | High | ISO, Oeko-Tex | Europe, Global | Automotive, Apparel |

| Kuraray Group | Japan | Innovative | Moderate | ISO, REACH | Asia, Global | Technical, Apparel |

| YKK | Japan | Durable | Moderate | ISO, Oeko-Tex | Global | Apparel, Automotive |

| Berry Global | USA | Broad | Moderate | ISO, REACH, RoHS | Global | Packaging, Medical |

| Avery Dennison | USA | Versatile | Moderate | ISO, Oeko-Tex | Global | Apparel, Packaging |

| VEKEN | China | Comprehensive | High | ISO, Oeko-Tex, REACH | Global | Garment, Accessories |

Buyers can use this table to compare tape companies and identify which manufacturer best aligns with their requirements. VEKEN’s strengths in customization, quality assurance, and global logistics make it a standout choice for garment accessories and trims.

🚀 For more details on VEKEN’s garment trims and hook and loop tape solutions, visit VEKEN Garment Trims Collection.

Scenario-Based Recommendations

High-Volume Orders

Buyers managing large-scale production require factories with robust capacity and efficient logistics. Leading adhesive hook and loop suppliers support high-volume orders with advanced machinery, automated warehouses, and global export reach. The table below highlights key features that benefit bulk buyers:

| Feature | Details |

|---|---|

| Production Capacity | Over 1,000 tons of webbing and tape per year |

| Warehouse Size | 30,000 m² automated warehouse |

| Machinery | 2,000+ weaving & knitting machines |

| Export Reach | 150+ countries & regions |

| OEM/ODM Capability | Strong, with stable quality control |

| Certification | OEKO-TEX certified |

Factories like VEKEN excel in handling high-volume adhesive hook and loop orders for global garment and industrial applications.

Custom Garment Accessories & Trims

Fashion brands and apparel manufacturers often need custom trims for unique applications. Top companies offer OEM and ODM services, material customization, and eco-friendly options. The table below outlines customization capabilities:

| Customization Type | Description |

|---|---|

| OEM | Full-scale production based on client designs |

| ODM | In-house R&D for new trim concepts |

| Material Customization | Options for various materials to fit specific applications |

| Eco-friendly Options | Sustainable materials for green applications |

| Branding & Packaging | Custom branding and packaging for differentiation |

VEKEN provides tailored adhesive hook and loop solutions, supporting creative garment applications and sustainable fashion initiatives. Explore more at VEKEN Garment Trims Collection.

Fast Delivery Needs

Urgent projects demand suppliers with proven on-time delivery records. Several companies achieve near-perfect delivery rates, ensuring adhesive hook and loop products arrive quickly for time-sensitive applications.

| Supplier | On-Time Delivery |

|---|---|

| Shenzhen Zhongda Hook& Loop Co., Ltd. | 99.2% |

| Guangzhou Balance Daily Commodities Co., Ltd. | 100.0% |

| Shenzhen Hongxiangwen Hook & Loop Co., Ltd. | 100.0% |

| Zhongshan Liyao Weaving Co., Ltd | 99.1% |

| Ningbo MH Industry Co., Ltd. | 100.0% |

🚚 Fast delivery supports urgent production schedules and seasonal applications.

Budget Solutions

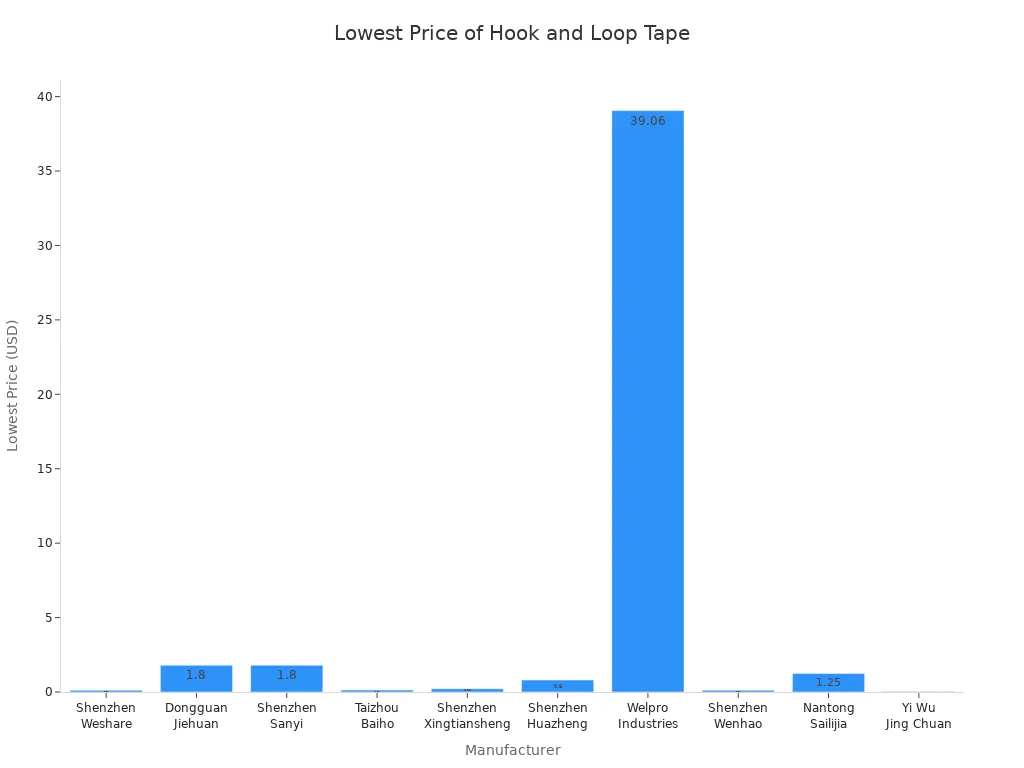

Cost-sensitive buyers can find adhesive hook and loop suppliers offering competitive prices and flexible minimum orders. The chart below compares price points among leading manufacturers:

Companies such as Shenzhen Weshare New Material and Taizhou Baiho Industrial provide affordable options for everyday applications, making them suitable for budget-driven projects.

Premium Quality

High-end applications require premium adhesive hook and loop products with advanced performance. Leading companies in this segment include:

| Company Name | Location | Specialization |

|---|---|---|

| Shenzhen Fucheng Hook&Loop Co., Ltd. | Guangdong Province | Synthetic textile manufacturing |

| Shenzhen Zhongda Hook& Loop Co., Ltd. | Guangdong Province | Vertically integrated factories |

| Dongyang Jinfeng Textile Co., Ltd. | Zhejiang Province | Custom development and rapid prototyping |

- 3M and Velcro Companies lead in innovation for demanding applications.

- Shin-Etsu Chemical and YKK Group deliver reliable fastening for technical applications.

- Henkel Adhesives supports industrial and specialty applications.

🏆 Premium suppliers ensure consistent quality for critical applications in medical, aerospace, and luxury apparel.

Validating Factory Choice

Selecting the right hook and loop tape factory requires a structured validation process. Buyers can reduce risk and ensure consistent quality by following several best practices.

Pilot Orders & Samples

Buyers often start with pilot orders or request physical samples. This step allows them to test the tape’s properties, such as peel strength and temperature resistance, before committing to large orders. They can also:

- Request physical samples to check material quality and adhesion.

- Conduct factory audits through virtual tours or third-party inspections.

- Review performance metrics, including on-time delivery rates and reorder frequency.

- Require third-party testing reports for safety-critical applications.

🧪 Tip: Testing samples in real-world conditions helps buyers confirm that the tape meets their application requirements.

Case Studies & References

Real-world examples and references provide insight into a factory’s reliability. Buyers should ask for:

- Third-party lab testing results, such as abrasion resistance and peel strength.

- On-site or virtual audit reports.

- Customer references or detailed case studies from similar industries.

- Reviews of ISO, OEKO-TEX®, or REACH certifications.

- Observations on response time and communication clarity during initial inquiries.

These references help buyers evaluate the factory’s track record and responsiveness.

Certifications Check

International buyers often verify certifications to ensure compliance and product safety. The SGS certificate remains the most frequently checked. It confirms that the tape has passed independent testing against defined standards. Key elements of a valid SGS certificate include:

- A unique report number, verifiable on sgs.com/verification.

- A detailed product description, including materials and specifications.

- Test parameters, such as pull strength and temperature resistance.

Buyers should always request up-to-date certification documents and verify them through official channels.

By following these steps, buyers can confidently select a hook and loop tape factory that meets their quality, compliance, and delivery expectations.

Innovation & Trends In Adhesive Hook And Loop

Eco-Friendly Options

Sustainability drives new trends in adhesive hook and loop manufacturing. Companies now focus on reducing environmental impact across all applications.

- In March 2023, Velcro Companies launched bio-based hook and loop fasteners. These products help lower the carbon footprint in the market.

- Environmental regulations encourage the use of recyclable and biodegradable adhesive hook and loop tapes.

- Manufacturers develop new materials that support eco-friendly applications, including recyclable and compostable options.

Buyers see more choices for sustainable adhesive hook and loop solutions. These trends reflect a growing demand for responsible sourcing in garment accessories and industrial applications.

🌱 Eco-friendly adhesive hook and loop tapes support green initiatives in apparel, packaging, and consumer electronics applications.

Technology Advances

Recent advances in technology improve the performance and durability of adhesive hook and loop tapes. Companies invest in new materials and production methods to meet the needs of modern applications.

| Innovation Type | Impact on Performance and Durability |

|---|---|

| Materials and Functionality | Enhanced durability, lighter weight, specialized properties such as heat and chemical resistance |

| Eco-friendly Alternatives | Expanding appeal of adhesive hook and loop tape products |

Factories use advanced polymers and weaving techniques to create tapes for demanding applications. These innovations help companies deliver reliable fastening solutions for automotive, aerospace, and medical applications.

Evolving Buyer Needs

The adhesive hook and loop market adapts to changing buyer requirements. Companies respond by investing in technology and expanding service offerings.

| Buyer Requirements | Factory Adaptations |

|---|---|

| Sustainability | Investing in advanced manufacturing technologies |

| Customization | Diversifying supplier networks |

| Value-added services | Enhancing service offerings to meet evolving demands |

| Competitive Focus | Strategic Actions |

|---|---|

| Speed to market | Collaborating on co-developed solutions |

| Sustainability commitments | Publishing roadmaps for recyclable constructions |

Buyers now expect fast delivery, custom adhesive hook and loop solutions, and transparent sustainability practices. Companies publish clear roadmaps for recyclable constructions and work closely with clients to develop new applications. These trends shape the future of adhesive hook and loop products in global markets.

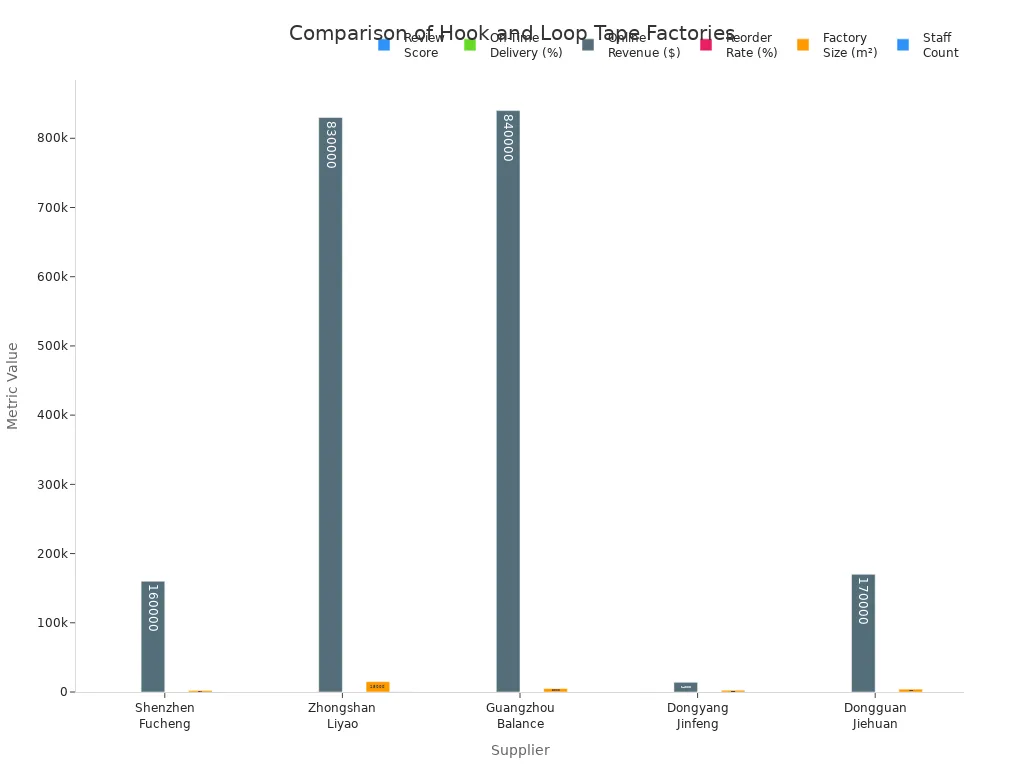

Buyers should compare each hook & loop tape factory by reviewing on-time delivery, response time, certifications, and sample testing. The table below highlights supplier performance for critical applications:

| Supplier | Review Score | On-Time Delivery | Response Time |

|---|---|---|---|

| Shenzhen Fucheng Hook&Loop Co., Ltd. | 4.9/5.0 | 96.2% | ≤3h |

| Zhongshan Liyao Weaving Co., Ltd | 4.4/5.0 | 99.2% | ≤6h |

| Guangzhou Balance Daily Commodities Co., Ltd. | 4.9/5.0 | 100.0% | ≤3h |

Selecting the right partner ensures reliable supply for diverse applications. VEKEN offers tailored solutions for garment accessories and trims, supporting buyers in every application.

FAQ

What factors should buyers consider when choosing a hook and loop tape factory?

Buyers should evaluate product range, customization options, quality certifications, pricing, delivery reliability, and after-sales support. These factors help ensure the factory meets specific application needs and industry standards.

How can buyers verify the quality of hook and loop tape?

Buyers can request product samples, review third-party test reports, and check for certifications like ISO 9001 or Oeko-Tex. Testing samples in real-world conditions confirms performance and durability.

What is the typical lead time for custom hook and loop tape orders?

Lead times vary by factory and order size. Most factories deliver standard orders within 7–15 days. Custom or large-volume orders may require 20–30 days. Buyers should confirm timelines before placing orders.

Are eco-friendly hook and loop tape options available?

Many factories now offer eco-friendly hook and loop tapes. These products use recycled or biodegradable materials and meet environmental standards. Buyers should request documentation to verify sustainability claims.

How do buyers handle after-sales issues with hook and loop tape suppliers?

Buyers should contact the supplier’s support team directly. Leading factories provide clear after-sales policies, including replacements or refunds for defective products. Prompt communication ensures quick resolution.

Quick Link

Contact

Address

Floor 18, Yuehu Jinhui Tower, 225 Liuting Street Haishu District,Ningbo,China 315010

Copyright © 2025 , All rights reserved. Powered by ningbo v.k. industry & trading Co., Ltd.