-40°C Extreme Cold Validation: Veken Sodium Battery Winter Testing in Hailar

Table of Contents

Real-World Data from Northern China’s Coldest Automotive Test Environment ❄️

In January 2026, Veken completed a full-scale extreme cold winter validation test for its sodium-ion battery systems in Hailar, Hulunbuir, Inner Mongolia, one of China’s coldest automotive testing regions.

The project, conducted jointly with Jujiang Group, focused on validating sodium battery performance in real winter driving conditions below –35°C, with recorded lows reaching –39°C.

This article explains what was tested, how it was tested, and why the results matter for B2B buyers evaluating low-temperature vehicle power solutions, especially for commercial vehicles, cold-region fleets, and auxiliary power systems.

📍 Test location image suggestion: Hailar winter test field, snow-covered vehicles

🖼️ (Insert image: Extreme cold automotive testing environment)

Why Hailar Is a Benchmark for Extreme Cold Battery Testing

Hailar is widely used for winter vehicle validation because it closely represents real operating conditions in northern China and other sub-arctic regions.

Key environmental characteristics:

🌡️ Ambient temperature: consistently below –35°C

❄️ Natural cold soak: no artificial temperature control

🚚 Real vehicles: commercial and passenger vehicles under daily use patterns

Unlike laboratory cold chambers, Hailar testing reflects actual user behavior, including parking duration, repeated cold starts, and auxiliary power demand during idling.

Products Covered in the Winter Test Program 🔋

The winter validation included multiple sodium-ion battery power products, covering both commercial vehicles and passenger vehicles:

Tested Sodium Battery Applications

Commercial vehicle engine start & parking power systems

Commercial vehicle engine starting batteries

Passenger vehicle start-stop power batteries

All tested products were equipped with Veken’s self-developed Battery Management System (BMS), designed to maintain operational stability across a wide temperature range from –40°C to +70°C.

📌 Application image suggestion: Commercial truck cold start testing

🖼️ (Insert image: Truck cold start test in winter)

Test Structure: Four Real-World Validation Stages

The winter test followed a structured, scenario-based approach, divided into four main stages to reflect real user behavior.

1. Cold Start Performance Validation 🚗

Multiple cold start attempts after long cold soak

Different state-of-charge (SOC) levels

No external heating assistance

Result:

At –39°C ambient temperature, several sodium battery products successfully completed engine ignition, confirming stable high-current output in extreme cold.

2. Cabin Heating Power Supply Validation 🔥

Continuous power supply for diesel heaters

Extended operation during low-temperature parking

No auxiliary charging or heating

Result:

The sodium battery systems maintained stable discharge output to support cabin heating under sub-zero conditions.

3. Parking Air-Conditioning Discharge Test ❄️

Continuous low-temperature discharge

Simulated overnight parking scenarios

Repeated load cycles

Result:

Battery voltage and discharge behavior remained stable during prolonged low-temperature operation.

4. Long-Term Vehicle Follow-Up Testing 🛣️

Daily vehicle use simulation

Repeated start-stop cycles

Variable parking duration and SOC conditions

Result:

The batteries demonstrated consistent performance across repeated winter usage cycles, supporting long-term reliability assessment.

Why Sodium Batteries Perform Differently in Extreme Cold

One of the key technical factors in this test was the NFPP polyanionic material system used in the sodium battery cells.

Key Characteristics of NFPP-Based Sodium Batteries

Better low-temperature ion movement

More stable structure during charge and discharge

Reduced performance drop at low temperatures

Practical Meaning for B2B Users

Without relying on external heating systems, the tested sodium batteries were able to:

Deliver high current for cold engine starts

Support continuous auxiliary loads

Maintain repeatable performance in extreme cold

This makes sodium-ion batteries a practical option for cold-region vehicles, especially where low-temperature reliability is a priority.

📊 Visual suggestion: Low-temperature discharge comparison chart

🖼️ (Insert image: Battery discharge curve at –40°C)

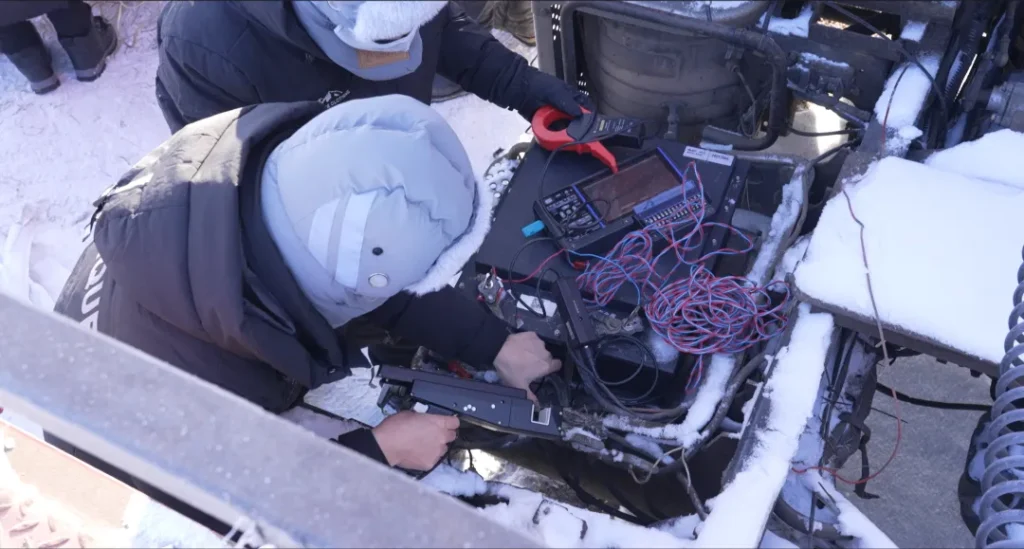

On-Site Execution and Data Reliability 🔍

To ensure data accuracy, Veken deployed a cross-functional on-site team, including:

R&D engineers

Test and validation specialists

Field data recording staff

All test equipment was calibrated on site, and performance data was collected directly from real vehicle operation, not simulations.

This approach strengthens data credibility, which is essential for B2B procurement decisions involving vehicle power systems.

Real-World Use Cases for Extreme Cold Sodium Batteries

Based on the test scenarios, the validated sodium battery systems are relevant for:

🚛 Commercial vehicles operating in cold regions

❄️ Northern logistics fleets with overnight parking

🚐 Vehicles requiring stable auxiliary power in winter

🛠️ Fleet operators seeking alternatives to lead-acid batteries

These use cases are common in Northern China, Central Asia, Eastern Europe, and similar climates.

About Veken: Verifiable Background Information

Veken is part of Ningbo Veken Group, a diversified industrial group with manufacturing foundations in China, including its own textile factories and large-scale production capabilities.

Key factual points:

Established industrial manufacturing base

Experience in large-volume order fulfillment

Focus on battery systems and industrial products

🔗 Battery product overview:

https://vekenindustry.com/battery/

🔗 Company contact page:

https://vekenindustry.com/contact-us/

(All links provided are official company pages for reference and verification.)

What This Winter Test Demonstrates for B2B Decision-Makers

This Hailar winter validation provides clear, real-world evidence of sodium battery behavior under –40°C extreme cold conditions.

Key Takeaways

Sodium batteries can support reliable cold starts at –39°C

Stable discharge is possible without external heating

Real vehicle testing improves data trustworthiness

Applicable to commercial and passenger vehicle power systems

For B2B buyers evaluating low-temperature vehicle battery solutions, field-tested data like this is critical for risk assessment and system selection.

Data-Driven Validation, Not Laboratory Assumptions

Extreme cold performance cannot be proven in theory alone.

By completing multi-scenario winter testing in Hailar, Veken has provided fact-based validation of sodium-ion battery systems under real winter operating conditions.

For industries operating in cold climates, this test offers practical reference data, not assumptions.❄️🔋

Quick Link

Contact

Address

Floor 18, Yuehu Jinhui Tower, 225 Liuting Street Haishu District,Ningbo,China 315010

Copyright © 2025 , All rights reserved. Powered by ningbo v.k. industry & trading Co., Ltd.